Harold Tichenor continues his series of articles on reel-to-reel tape in this article on restoration copies.

Dr. David W. Robinson, Editor-in-Chief

Harold Tichenor at work on a RTR setup...

Restoration copies are made from tapes that are deteriorating through wear, age, or inherent flaws. They are the means of assuring that the content is not lost when the source tape completely fails. They may require drawing on several different source tape copies to assemble a new, hopefully flawless program. In extreme cases, even digital sources made from previous releases may be needed to replace a damaged or lost section of the original tape. As tapes age each type of stock has had its problems often requiring these restoration efforts.

Acetate-based tapes had an advantage that when they broke, they usually did so cleanly without stretching. So, a tape snap could be easily repaired with the application of a splice, a bit of fine adhesive tape applied to the back of the tape while the broken ends are held in contact. This is basically the same procedure used in physically editing or "cutting" tape.

With age some of the splicing tape materials themselves have failed. Or their adhesive may degenerate and become gummy causing layers of tape to stick together in the reel. To restore such tapes involves carefully winding at low speed through the whole reel, removing each failing tape splice and cleaning off the residue of glue before applying new splicing tape.

There is considerable debate on what fluid to use to clean adhesive residue. I generally use pure ethanol applied lightly with a Q-tip. Others suggest lighter fluid, naphtha, denatured isopropyl alcohol, WD40, eucalyptus oil and other volatile substances. It is best to try applying a bit of the fluid to an unused area of the tape to see if it will cause problems. If possible, preparing a protection copy before the repairs is advisable.

A third issue that can be faced with acetate-based tape is vinegar syndrome quite often found with Kodak brand audio tape from the 1960s. Often there is a distinct sour odour of vinegar on opening the box or container and the tape itself will unspool in uneven loops and is warped or twisted. There is no known corrective for this degeneration and the best course is to prepare a restoration copy as soon as the problem is recognized. Some tape playback machines are better than others at maintaining tension sufficient to keep the twisting emulsion in contact with its heads. The variations in shrinkage of the tape will inevitably introduce some wow and flutter into the copy being made.

Acetate motion picture film and audio tape both can suffer from vinegar syndrome. Credit

A fourth issue with acetate-based tapes is dry shedding. Here the emulsion flakes off as fine dust or in worse cases it actually peels off in long continuous sheets. In mild cases, a restoration copy can be made after allowing the tape to sit in a humid area for a day or so. There appears to be no way to reverse this issue and making a restoration copy immediately is recommended. Where the emulsion threatens to come off in long continuous sheets the only method that might work is to use a transfer deck with the least "bends" in its threading path and to transfer at the lowest speed possible.

Dry shedding from acetate tape where the emulsion peels off the base during transport. Credit

Finally, acetate-based tapes may also "squeal" during playback. The most common cause of this is desiccation of the lubricants in the emulsion or base. In mild cases, a light application of a silicone-based fluid like Dow 244 throughout the length of the tape, followed by removal of all excess silicone coating can produce a tape capable of being restoration duplicated.

Polyester-based tapes have their own potential issues. Some may squeal like acetate tapes and treatment with silicone can provide a temporary fix. More serious however, if a polyester tape is subjected to a sudden severe increase in tension, it will actually stretch and not snap cleanly as acetate does. There is no repair for a stretched polyester tape; the damaged section must be removed and in archival situations it should be replaced with an equivalent length of blank tape indicating how much material was lost. If there are other sources for the program content it is also possible to create a replacement segment by matching the volume accurately and editing it into place.

The most common problem with polyester based back coated tape is Sticky Shed Syndrome. Around 1980 several major tape manufacturers modified the formula for the binders used to affix the emulsion and the back coating to the tape stock base. Only after a decade or so it was discovered that these new binders had degenerated, apparently from exposure to humidity. This allowed the binder material to shed from the tape and stick as a gooey mass on the guides and heads of the recorder, making playback impossible. In some cases, tapes became so damaged that there was no means of repair or salvage. A large body of studio master material has been lost to this phenomenon.

Sticky shed syndrome first shows up as a gummy deposit on the guides, heads and capstan. Credit

In early diagnosed and less severe cases, it was discovered that subjecting the tapes to a "baking" and cooling process allowed a temporary period of time in which the tape could be safely played. Making a restoration copy at this point is the only permanent solution. In time, the source tape degenerates once again, but can also be baked again; how many cycles of this process can be carried out before permanent failure of the tape is unclear. By the end of the 1990s the problem had been identified and it is hoped that newer emulsions will not suffer from the syndrome.

Unfortunately, however “tape baking” has become a popular topic and is often recommended for tapes suffering from virtually any kind of technical issue. However, baking should only be used to correct sticky shed syndrome; many other tapes, especially acetate-based ones can be damaged or destroyed if subjected to this hot, desiccating process. I have seen the emulsion of acetate masters softened and then when cooled bind to the base of the next layer in the wind. When these sections are unspooled, the emulsion is stripped off the tape and the segment if no longer playable.

Both acetate and polyester/mylar tapes can become moldy if improperly stored in high humidity. Usually, the mold can be removed by winding the tape through a cleaning cloth at a moderate speed. Pellon cloth, available at most sewing and fabric stores, is an excellent choice for this purpose.

Mold growing on the edges of the tape can be wiped off and usually will not reappear unless the tape is stored in a damp environment. Credit

All tapes of whatever base material can have issues arising from how they were handled and spliced. Masters often have white paper leader used to separate different songs or movements on the tape, creating bands or "spirals." During winding or rewinding at high speed the splices joining these paper spacers often fail and can lead to massive tape spills. The correct process is once again to wind through the tape at low speed, locate and replace every spice and often the white paper leader itself if it appears to be fragile or misshapen.

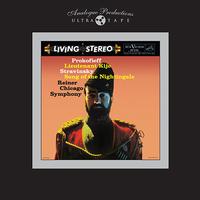

A copy master with white leader between the individual bands which are also referred to as spirals. The variations in color show the different stock types for each band and are typical of a master built up from various work parts or program sources.

On edited work parts there literally can be hundreds of splices that may need to be replaced. Removing the old tape and residual gum can be extremely difficult and if not properly done can lead to actual damage of the tape at the splice points. If possible, it is best to make a protection copy of the tape prior to undertaking this type of restoration work. And then prepare a restoration copy on completion.

Finally, tapes should be stored in clean plastic or cardboard boxes in an area of moderate temperature and humidity. 60% humidity and 60 degrees F or 15 degrees Celsius are reasonable targets for a private collection. Tapes that are made to be played only in one direction are generally stored with their tails out; while tapes recorded to play two sides by flipping the reel at the end of the first side, are generally stored with the first side heads out.

More to come in the near future.