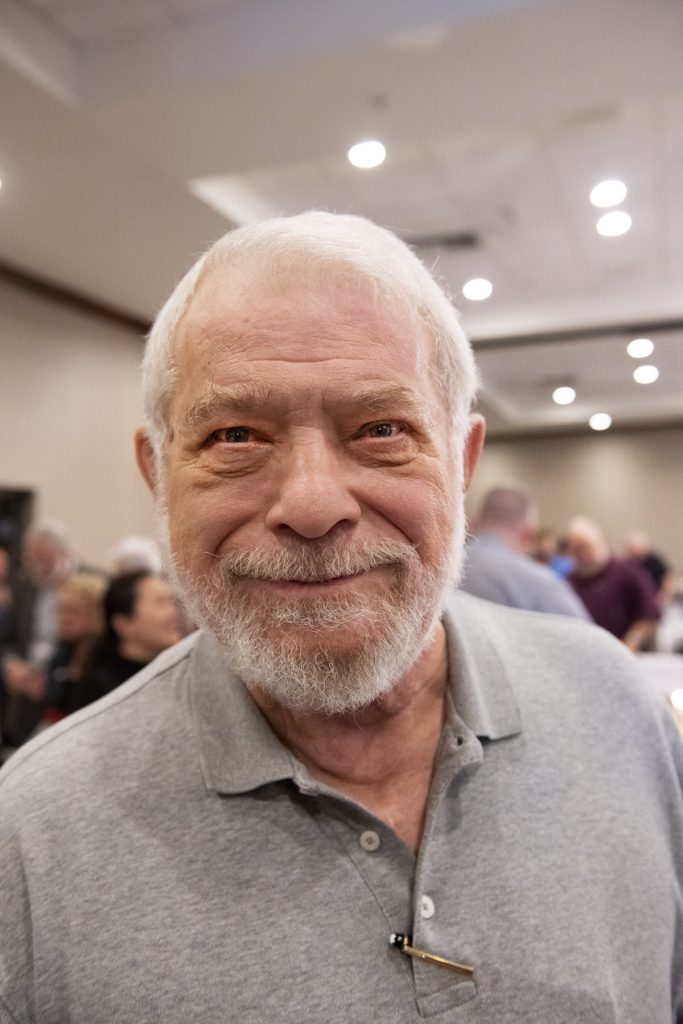

Roger Skoff at the LAOC Audio Society Gala Banquet, 2018: a portrait by David W. Robinson

In Part 1 of this two-part article, I pointed out that we audiophiles are the only fan group I know of who argue, not just about which stuff is better, but about whether, for some products, there's any difference at all!

We do this, I said, about any number things (amplifiers, various tweaks and treatments, and so forth) but most of all, we argue about cables. And, because a great many of us DO hear a difference, we also argue about whether our hearing is to be trusted in such matters or, if in the absence of double-blind testing, it might all just be "placebo effect" and we're not really hearing those differences at all.

There are excellent reasons why double blind testing doesn't and can't work for audio gear and, if your responses to this article indicate that you want me to state them, I will do so in some future article. In this one, though, I'm going to proceed as if we've already accepted that just listening is sufficient to truly show sonic differences in cables, and go on to tell you about what some of the factors that contribute to those differences are.

First, though, in the spirit of full disclosure, let me tell you that I am a cable designer; that I do believe that cables play a critical role in allowing your system to deliver all of the performance that you pay so much to buy; and that I will soon be bringing a new and very specialized line of cables to market (RSX Audio), for which this article may just be shameless pandering…

Or it might be valuable truth that will help you to better enjoy your system. Read on, and decide for yourself.

The first thing to know is that cables are exactly what the average person might say if you asked him: Just something to get signal from one point to another. That's it; nothing more. And just as, if you hire someone to deliver something for you, you expect all of whatever it is to arrive at its destination in the same condition as when you sent it, with no changes, additions, or subtractions whatsoever. Cables are exactly the same: Other than getting what you want to where you want it, the ideal cable will do exactly nothing at all.

And that's where the problem lies. Although the cable doubters insist that "wires is wires," and have a hard time imagining that any properly-designed, well-built cable in good condition could ever, in any way, affect the sound of the signal it carries, the fact of the matter is that to get a cable to NOT affect the sound of your system is fiendishly difficult, and may even be impossible.

Let's see how. Let's start by simply accepting the engineers' favorite factors for cables: R (resistance), C (capacitance), and L (inductance). They say that those things make a difference, and it's true. Among other things, they can affect both the power level passed by a cable and its frequency response.

In thinking about this, remember a couple of things. First, that "resistance" is a term best applied to DC (direct current), and that with AC (alternating current) signals like music, wherever there is capacitive or inductive reactance (as there always is in cables), the more correct term to use is probably "impedance" (Z).

Second, remember that inductance, one of those favored factors, "…is the property of an electrical conductor by which a change in electric current through it induces an electromotive force (voltage) in the conductor." (read more HERE) What that means is that any current flowing through a conductor causes an electromagnetic field to form around that conductor (and out to infinity, in accordance with the "inverse-square law"), and that, when the direction of that current changes (as it does every time the AC current changes polarity) the field collapses and the collapsing field creates a voltage ("back EMF") that opposes the flow of incoming new signal. The higher the frequency, the more of an effect this has on the sound.

Remember, also, that capacitance, another of the "favored factors", is the ability to store energy (read more HERE), and that a capacitor is formed any time two conductors ("plates") are brought together, separated by a non-conductor "dielectric" (read more HERE). What that means is that every cable is, by definition, a capacitor, with its two conductors (positive and negative or "going" and "coming") being the plates, and the insulation between them being the dielectric.

Now, have you ever noticed that, when electronics designers or engineers call for a capacitor to be included in a circuit, they not only specify its capacitance, but also its type? (Ceramic, Film and paper, Polymer, air gap, mica, tantalum, and many, many others (read more HERE and HERE). If factors other than just the measured capacitance of a capacitor are important (and can make a performance difference) in other types of capacitors, how can those exact same things not make a difference in cables?

The amount of capacitance—and of inductance—in any cable or other capacitor is largely determined by how far apart the "plates" are spaced, with those two factors in a sort of "seesaw" balance: The more capacitance there is, the less inductance, and vice versa.

Another very major factor is the material that the dielectric is made of: For cables, virtually all of the various non-conductive elements are part of the dielectric. This is important in two ways: The first is that different dielectric materials have different dielectric constants (the ratio of the capacitance of a capacitor in which a particular insulating material is the dielectric, to its capacitance in which a vacuum is the dielectric, read more HERE). Or, to put it most simply, the dielectric constant of a material is a number that shows how much energy any given volume of it can store as compared to that same volume of vacuum. By way of illustration, the dielectric constant of a hard vacuum is 1.0, while balsa wood (a little stiff for most cables) is 1.4. Teflon® (there are several varieties) is around 2.0. Polyethylene is around 2.2, and PVC and TPR (thermoplastic rubber), the two most popular cable insulators, by far, can have dielectric constants of as high as 6.8 (read more HERE).

Whatever the amount of stored energy, when the signal carried by the cable changes polarity, all of that energy is dumped into the signal path, canceling some of the incoming signal, or actually creating out-of-phase artifacts. This results in either the loss of low-level information or the actual creation of new information, either of which would be surprising if it didn't affect the sound!

The other important thing about dielectrics (which, remember, include the non-conducting elements of a cable) is their "dump rate"—how quickly they can release stored energy after the signal changes polarity so that they can start storing the new signal energy coming in. Dump rates vary wildly, with some materials, PVC, for example, being quite (relatively) slow and others (Teflon®, for example) being very, very fast. This can make a definitely audible difference (with faster dump rates that affect the incoming signal for less time being much preferred), and, surprisingly, the dump rate of a material and its dielectric constant are not directly proportional. Polyethylene is only around ten percent higher in dielectric constant than the best form of Teflon®, but has—while still vastly faster than PVC—an audibly slower dump rate, to lose low-level detail and "muddy" its sound.

There are still other factors that affect the sound of a cable—its "geometry"; the type, purity and crystal structure of the metal in its conductors: the existence of mysterious (and perhaps mythical) micro-diodes at the crystal junctures of copper; the self- and mutual-inductance of both the cable and its connectors; how much and what kind of metal those connectors are made of, and many more, but I'm out of space for now.

Perhaps another time.

Cartoon by Bruce Walker